Introduction

In recent years, the drive towards sustainability has gained unprecedented momentum. Businesses across various sectors are recognizing the need to adopt greener practices, and one of the most impactful methods is the installation of solar panels. This shift is particularly crucial in food processing plants, where energy consumption is typically high and operational costs can be substantial. This article delves into The Importance of Installing Solar Panels in Food Processing Plants and discusses how this technology can not only enhance energy efficiency but also contribute to long-term financial benefits.

Solar energy for manufacturing has emerged as a viable solution for reducing dependency on fossil fuels while lowering greenhouse gas emissions. With the rising costs of energy, many food processing facilities are now exploring ways to harness renewable energy sources through factory solar panel installation. industrial energy solutions By leveraging commercial solar panels in the UK, food manufacturers can achieve significant cost savings and improve their overall sustainability.

Understanding Solar Energy

What is Solar Energy?

Solar energy refers to the power derived from sunlight that can be converted into thermal or electrical energy. Through photovoltaic cells, solar panels capture sunlight and convert it into electricity. This renewable resource offers a clean alternative to traditional fossil fuels, making it a popular choice for commercial enterprises.

How Do Solar Panels Work?

Solar panels utilize photovoltaic cells made from silicon to absorb sunlight. When sunlight strikes these cells, it excites electrons and generates direct current (DC) electricity. An inverter then converts this DC electricity into alternating current (AC), which is used to power machinery and equipment within food processing plants.

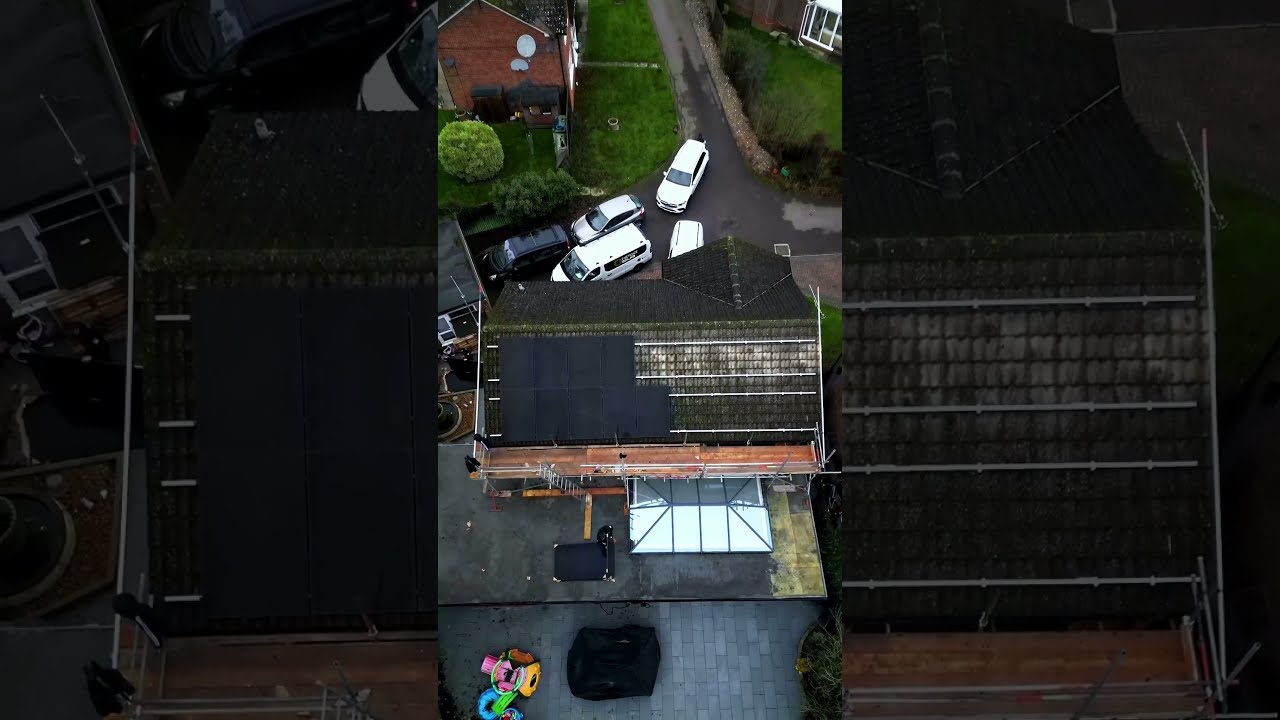

The Mechanics of Solar Panel Installation

Solar panel installation involves several steps:

Site Assessment: Experts evaluate the facility's roof structure and orientation to determine the best placement for maximum sun exposure. System Design: Engineers design a custom solar system tailored to the facility's energy needs. Installation: Trained professionals install solar panels on the roof or ground-mounted systems. Connection to Grid: The solar system is connected to the local utility grid, allowing for net metering options. Monitoring & Maintenance: Ongoing monitoring ensures optimal performance, while maintenance addresses any potential issues.The Role of Solar Panels in Food Processing Plants

Energy Consumption in Food Processing Facilities

Food processing plants often operate with high-energy demands due to various processes such as refrigeration, cooking, packaging, and storage. This leads to elevated utility costs that can significantly affect profit margins.

Benefits of Solar Panels for Factories

1. Cost Savings on Energy Bills

Installing solar panels enables food processing plants to generate their own electricity, significantly reducing reliance on external power sources and leading to lower monthly utility bills.

2. Environmental Impact Reduction

By switching to renewable energy sources like solar power, facilities can substantially decrease their carbon footprint and contribute positively towards environmental conservation efforts.

3. Energy Independence

Adopting solar energy fosters greater independence from fluctuating energy prices and helps businesses stabilize their operating costs over time.

Types of Solar Solutions for Food Processing Plants

Industrial Solar Panel Systems Available Today

Food processing facilities have access to various types of industrial solar panel systems:

- Rooftop Solar Systems Ground-mounted installations Hybrid systems combining different forms of renewable energy

These options cater specifically to verticals like food manufacturing where space may be limited or specific structural considerations apply.

Commercial Rooftop Solar Installations: A Practical Approach

Rooftop installations maximize available space without requiring additional land while providing efficient power generation directly where it's needed most—in-house operations.

Financial Considerations in Installing Solar Panels

Evaluating Factory Solar Panel Costs

When evaluating whether installing solar panels makes financial sense for your facility:

Determine upfront installation costs Calculate potential savings on monthly electric bills Assess available tax incentives or grants

Understanding Factory Solar Panel ROI (Return on Investment)

To gauge ROI effectively:

- Calculate total costs against projected savings over time Include considerations for maintenance expenses Factor in any government incentives that may apply

Government Incentives for Industrial Solar Installation

Exploring Industrial Solar Tax Benefits

Various programs exist that offer tax credits or rebates specifically designed to incentivize businesses transitioning towards renewable energy sources like solar panels.

Industrial Renewable Energy Certificates (RECs)

Businesses can earn RECs by producing clean energy through their installed solar systems—these can then be sold or traded Visit this link on renewable energy markets for additional income streams.

Challenges Faced by Food Processing Plants When Implementing Solar Solutions

Initial Capital Investment Concerns

While long-term savings are substantial, initial capital investments can deter some facilities from pursuing solar solutions without thorough financial analysis.

Space Limitations for Infrastructure Deployment

Some older food processing plants may struggle with adequate roofing structures capable of supporting additional weight from factory roof solar panels—this necessitates careful structural assessments before proceeding with installations.

Maintenance Considerations for Commercial Solar Panels in Food Processing Plants

Importance of Regular Maintenance Checks

Regularly scheduled maintenance checks ensure optimal performance levels throughout each season—this includes cleaning debris off panel surfaces, checking wiring connections, inspecting inverters, etcetera!

Commercial Solar Panel Lifespan Expectations

Most modern commercial rooftop solar installations boast warranties ranging between 20-25 years—a testament not only towards durability but reliability too!

Case Studies: Successful Implementation of Industrial Solar Solutions in Food Processing Plants

Here are some notable examples showcasing successful transitions:

| Company Name | Location | Installed Capacity | Annual Savings | |--------------|----------|-------------------|----------------| | XYZ Foods | UK | 500 kW | £30,000 | | ABC Snacks | USA | 300 kW | $15,000 |

Frequently Asked Questions (FAQs)

1. What are the costs involved in factory solar panel installation?

Costs vary based on system size but typically range from £50K - £250K depending upon complexity & scale requirements involved!

2. How much could our facility save annually by using industrial solar panels?

Annual savings depend upon existing utility rates; however many companies report reductions between 20%-60% after implementing these technologies!

3.Do we require planning permission when installing commercial rooftop solar?

In most cases no formal permissions are required unless there’s significant structural alterations involved—local regulations should always be consulted beforehand though!

4.What financing options exist specifically aimed at industrial solar projects?

Numerous lenders offer specialized financing packages targeting businesses looking towards sustainable alternatives including loans & leasing arrangements!

5.How do I monitor performance metrics associated with my installed system?

Most modern setups include integrated monitoring software allowing real-time insights into production levels against expected outputs—keeping tabs on efficiency becomes easier than ever!

6.Are there any risks associated with installing factory rooftop systems?

As long as proper assessments occur prior; risks remain minimal! Proper engineering evaluations mitigate concerns related structural integrity ensuring safe operations going forward!

Conclusion

In summation, adopting sustainable practices such as installing solar panels in food processing plants presents numerous advantages—from financial savings through reduced operational costs down environmental stewardship efforts aimed at combating climate change challenges facing today’s world! By understanding both technical aspects alongside financial implications surrounding these investments; decision-makers position themselves well within an increasingly eco-conscious marketplace eager seek innovative solutions driving future success stories ahead! Embracing these initiatives signals commitment towards responsible business practices that ultimately benefit everyone involved—from shareholders down customers alike!